Control TowerCloud

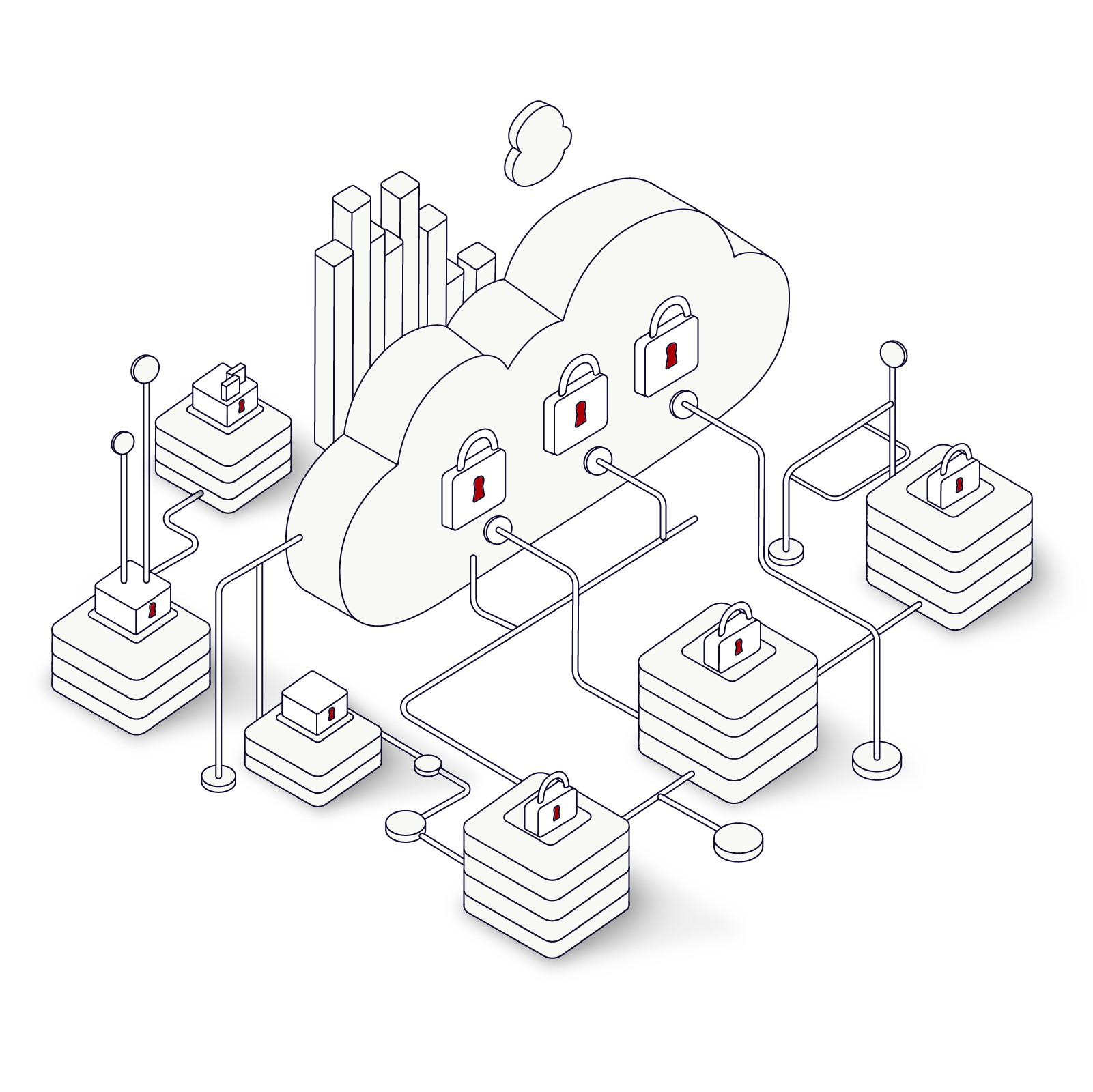

A scalable architecture that optimizes selective transfer of MATLAB data to the cloud and automates metadata extraction and indexing for efficient, targeted search.

AI system for diesel injector data analysis

For the Control Tower of Officine Meccaniche Torino, we adopted a highly scalable serverless architecture, capable of managing data relating to injection cycles coming from the research and development department, initially in MATLAB format. One of the central aspects is the decoupled architecture, which guarantees the transfer to the cloud only of files that are actually updated, optimizing both resources and available bandwidth.

Adapts resources to data without manual intervention.

Transfers only updated files, reducing bandwidth consumption.

Minimizes storage and compute waste.

Automatic processing and advanced search

Once loaded, an automatic event-based processing system extracts the essential metadata, storing it in a high-performance database. Thanks to this metadata, the web app offers extremely fast search: users can filter, consult and analyze the data in a targeted way, save customized searches, share them with the team and generate explanatory graphs.

The adoption of the serverless model allows to address any load peaks without requiring complex infrastructure interventions, also reducing the overall operating costs. In this way, OMT researchers and engineers can focus their resources on the in-depth analysis of injection cycles, relying on a solid and efficiency-oriented platform.

Infrastructure scalability and security

With this setting, the system can automatically scale based on the volume of data processed, dynamically adjusting the necessary resources and reducing waste.

Furthermore, serverless infrastructure guarantees high security standards, since file access is managed in a granular way and processing functions are activated only when required. This approach ensures clear cost control, avoiding expenses for idle or underutilized servers, and offers stable performance even as the workload grows.

Overall, the Control Tower provides a complete overview of injection cycles, promoting collaboration between research, development and production departments.

Looking for a skilled team to bring your next idea to life?

Fill in the form with your details and we’ll get back to you.